Relinea carried out a test to see what happens when a 76kg steel billet is dropped from height on Flow Forge Open Grating from height in comparison to Relinea’s RE-GRID3838 Open Mesh Grating.

Test Background and Procedure:

A number of identically dimensioned test samples were made from GRP (RE-GRID3838 Open Mesh

Grating) and steel (Flowforge Open Grating) and tested for impact resistance capabilities using a

drop test rig in the Civil & Structural Engineering Department in TCD. Although RE-GRID3838 and

Flowforge are not identical – Flowforge Open Grating is a steel, and therefore the connecting beams

need to be welded together and therefore the cross-sections are much different, Flowforge was

decided to be tested against Relinea’s RE-GRID3838 Open Mesh Grating as they are both used for

the same function.

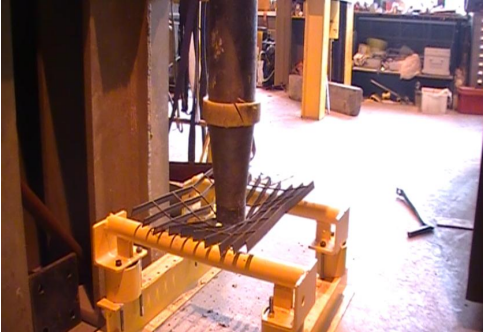

Regarding the test, a 76kg steel billet was released from rest from a number of different heights

onto both sample types. The test rig does not conform to any standard;

however the test was very useful in showing the differences in the elastic properties between the

two material types. The rig had a minimum set-up height of 0.62m and a maximum set-up height

of 2.75m. Each sample had a dimension of 550x400x38mm.

Results:

Flowforge Open Grating

As can be seen from Figure 1 –the result where the test was undertaken at

the minimum height of 0.62m – i.e. approximately a 5kN Force – the Flowforge panel was completely

elastically deformed due the force of the billet. The force of the billet can be measured from the

equation F = mgh. The steel plate absorbed all the force of the billet, but was not able to dissipate a

sufficient amount of the energy to prevent elastic deformation, and hence this phenomenon was

observed on the Flowforge Open Grating Panel on each test.

Figure 1

The GRP RE-GRID

On the other hand, all of the GRP RE-GRID test specimens were able to absorb all the energy of the

billet in all of the tests criteria – even up to a height of 2.75m: the equivalent of a 20kN Force. In

repeated testing of the same GRP samples; the fibres of that particular sample would eventually split

and the panel would eventually split in two. This however never happened in the first one-three

tests and would only happen occur after the 4th or 5th impact of the same sample. The Flowforge

samples on the other hand failed first time, every time.

Check out the results in the video!

Conclusions:

Steel – i.e. Flowforge Open Grating – exhibits very poor impact resistance properties. GRP however

exhibits excellent initial impact resistance properties; only failing after multiple testing of the same

specimen.