GRP Water and Wastewater Solutions

Combining our expertise in GRP Specialist Mouldings and Structural Products we can offer a vast range of GRP Products for the Water and Sewage Treatment Industries that outperform traditional materials and deliver highly durable solutions at a much lower cost.

Our expert team has a deep understanding of the challenges involved in these industries. Water companies, for example, are reacting to a future of increased competition brought about by market reform for non-domestic and domestic customers, with a focus on total expenditure (TOTEX) on assets and preparations for PR124 requirements. PR24, which will cover the period 2025-2030, will drive water companies to step up to deliver in the face of urgent challenges on the environment and climate change. The review will push companies to find new and innovative ways of delivering affordable, reliable, and resilient services for all.

Our team has unparalleled expertise in the planning, design, and installation of GRP systems for water supply infrastructure, treatment facilities, pumping stations, and water storage facilities. We bring industry-leading knowledge, as well as project management experience to complicated projects, and have worked with companies such as Glan Agua, Irish Water, Ovivo Water, various sewage treatment works and local councils.

Key Benefits of GRP Products:

- 75% lighter than steel – eliminating the need for heavy lifting gear and specialist equipment for installation

- Low Carbon footprint – 75% less energy is needed to produce GRP than steel and 50% less energy is needed for transport and assembly

- Anti-Corrosive – Even in highly aggressive areas, Relinea’s GRP Products offer excellent corrosive resistance

- Slip Resistance – 35% of all major injuries at work are caused by slips or trips. Our integral grit finish offers the world’s highest slip resistance for a walk-on surface

- Extended Life Cycle – A life span of 50 years with little or no maintenance expenditure means life cycle cost is vastly reduced

- Long-Term Cost Savings – Maintenance free, corrosion and impact resistant, our GRP products have considerably low life cycle costs compared to traditional materials. Plus, they hold zero theft value.

Relinea – Reliable, Resourceful

We innovate, design, and fabricate advanced technical GRP structural components to overcome weight, corrosion, and slip issues. With a revolutionary approach that uses intelligent GRP design and innovative composite manufacturing to challenge the conventions of construction, we work with our clients to find unique, long-lasting, sustainable solutions. From GRP design to installation, we are a specialist, one-stop resource.

Give us a call today on 028 9447 0010 or email us at info@relinea.com with your project specification to discuss your requirements and request a free quotation and proposal.

GRP Applications in Water and Wastewater

GRP Launder Channels

GRP Access Stairs

GRP Access Platforms

GRP Weir Plates

GRP Diffusion Drums

GRP Internal Walkways

GRP Baffle Plates

GRP Scum Boards

GRP Tank Covers

Related Case Studies:

Access Platforms

Coffey, working on behalf of Uisce Éireann to deliver this project brought us on board to design and fabricate a GRP walkway access system around the pipework in both the inlet and outlet valve houses. The walkway access platforms included ladders with safety cages and self closing gates.

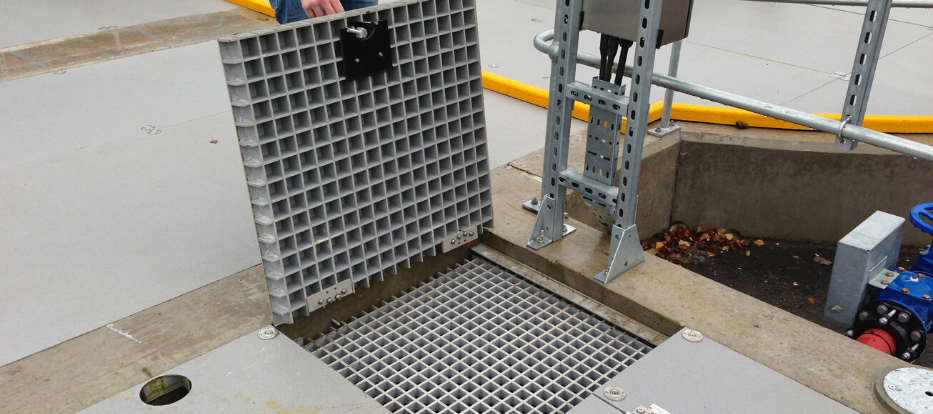

Access Hatches

The client needed a durable, safe and low cost solution for the trench covers, inlet channel covers, and access platforms. Steel is much more costly and would be very heavy to lift for the access hatches, it also would require much more maintenance.

Handrails

Glan Agua was aware that Relinea can offer a vast range of GRP Products for the Water and Sewage Treatment Industries that outperform traditional materials and deliver highly durable solutions at a much lower cost. We were brought on board this project to install our GRP handrails, stairs, and access platforms.

Tank Covers

The two sludge tanks to be covered were in full operation, hence the installation needed to be carefully co-ordinated with the client. To gain access within the sludge tanks, they would have had to be fully cleaned out, which would have proved to be very costly.