Aurivo Dairy Tank Covers

At a Glance

Share this:

Client

Aurivo

Location

- Roscommon

- , Ireland

Services

- Design, Fabrication, Installation

Products

- Tank Covers

Problem/Challenge

Aurivo faced the challenge of covering tanks efficiently without the need for extensive emptying and cleaning processes. Traditional covers made of steel or metal presented issues such as corrosion, weathering, and structural instability over time. Moreover, accessing the tanks for routine maintenance or inspections often proved to be cumbersome and time-consuming. The need for a solution that could address these challenges and align with industry standards, particularly WIMES 8.05, was critical.

Solution

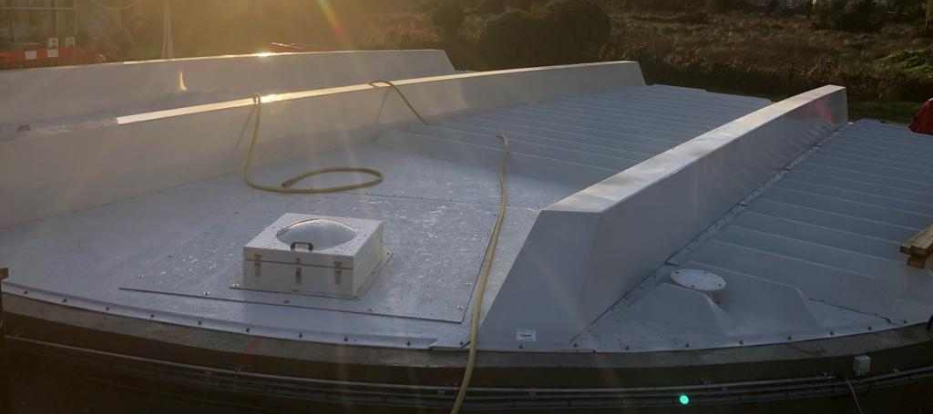

Relinea provided a comprehensive GRP beam and infill cover system designed, manufactured, and installed to meet the specific needs of the Dairy Industry. The GRP system offered an economical and efficient solution for covering the tanks, eliminating the need for tank emptying and cleaning during the installation process.

Designed in compliance with WIMES 8.05 standards, our GRP tank covers feature fully lockable access hatches with gas struts, ensuring secure and easy access for routine maintenance or inspections. The lightweight nature of the GRP covers not only simplifies the installation process but also guarantees longevity and durability. Unlike traditional steel or metal covers, our GRP covers are non-conductive, eliminating concerns related to electrical conductivity.

The benefits of choosing our GRP tank covers extend beyond the initial installation. With little to no maintenance required, our covers offer a cost-effective and hassle-free solution for the customer. Additionally, worries about corrosion, weathering, and structural instability are alleviated, as our GRP covers are resilient in various environmental conditions.

This successful project not only addressed the immediate challenges faced by our customer but also positioned our company as a reliable partner in providing innovative, compliant, and long-lasting GRP solutions.